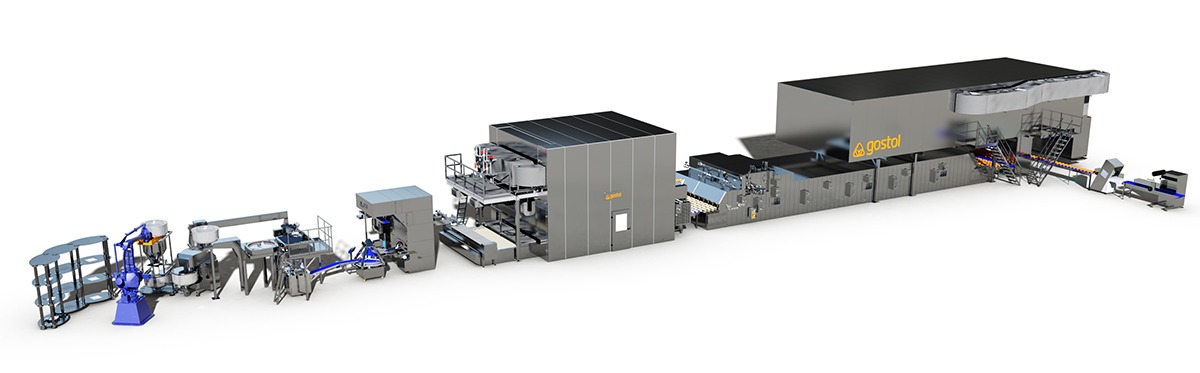

Line for tin bread with or without lidds

Bakery line for baking of tin bread are completely tailored to the buyer’s requirements. Such lines provided for production of wheat, wheat-rye, rye-wheat and rye tin bread. Industrial bakery lines for tin bread provide for the production capacity up to 7000 piece/h.

" Full automation. "

Advantages

- hygienic design of machineries

- line facilitated cleaning with design solutions (IK)

- easy line management

- only 1 person supervises the operating line

- easy and fast setting of machineries

- full machinery automation in the line

- management and supervision over operation trough the touch-screen panel

- possibility of production and baking of a wide range of products on trays, in moulds…

- possibility of production and baking of products with covers and without covers

- possibility of baking or oven use without the line operation (special products)

- change of products, moulds and trays on the line without any waiting time (bulk time)

- turn-key project from silos to packaging

Process phases

- Dough preparation (direct and indirect processes)

- Dough processing (make up)

- Fermentation

- Baking

- Products’ cooling

- Cutting and packaging

- Warehouse of pans and lids

- Products pasteurization

About

Gostol industrial lines for production of tin bread provide for an automated process of the tin bread baking. They are structured and completely adjusted to the shape and size of models, requested by a buyer. During the production process, tins’ manipulation itself takes place through numerous pan conveyors. Synchronization of the whole production process and also the transport itself provides for an effective production process, enables production of a high-quality tin bread with high production capacities (up to 7,000 piece/h).

On the line for production of a tin bread, products may be produced on tins, models with a lid, i.e. toast bread in models without a lid, the so-called pan bauletto or open top products.

The lines for production of a tin bread may be equipped also with an automatic warehouse of pans and lids.

Toasts produced on Gostol line are of a supreme taste, uniform porosity and colour.