< Back To Gostol Bakery Lines

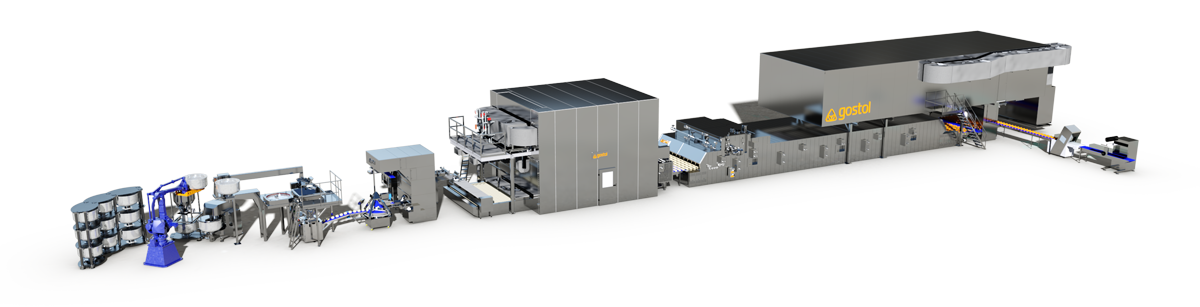

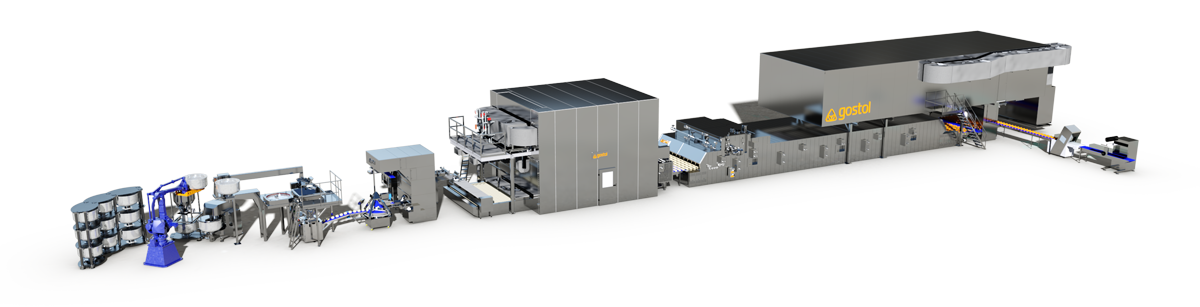

Line for free baked round bread

Gostol Group has been a specialist in the field of production of the industrial bakery lines for free-baked round loaves for many years. On such lines wheat, wheat-rye and rye-wheat or rye dough may be processed into round loaves. The line capacity may reach up to 5,000 piece/hour.

" Low energy consumption in entire bakery. "

Advantages

- hygienic design of machineries

- line facilitated cleaning with design solutions (IK)

- easy line management

- only 1 person supervises the operating line

- easy and fast setting of machineries

- full machinery automation in the line

- management and supervision over operation trough the touch-screen panel

- possibility of selecting a desired type of pocket /gutter corresponding to the product dimension

- possibility of baking or oven use without the line operation (special products)

- turn-key project from silos to packaging

Process phases

- Dough preparation (direct and indirect processes)

- Dough processing (make up)

- Fermentation

- Baking

- Products’ cooling

- Cutting and packaging

About

Shaped dough may be fermented in various types of pockets:

- wooden or plastic pockets,

- on tins in the chamber on the tins or

- on the belt in the tunnel chamber.

For baking of fermented products, there is an option of choosing various types of oven

- cyclothermic tunnel baking ovens of a new generation or thermal-oil ovens providing for the energy-efficient operation and reduction of C02 release in the environment. By means of recovery, the efficiency of the whole bakery is optimal, since only this provide for the re-use of residual heat. The third option is baking of free-baked long loaves in electric ovens.

Industrial lines are mono-productive, where only one form of a product may be produced, or combined ones, where free baked loaves as well as round loaves are produced as a combination.